- January 21, 2025

- No Responses

What is Hydraulic Impact Pile Hammer?

Overview

The hydraulic impact pile hammer is a modern piling system that utilizes hydraulic pressure to raise and lower a hammer (ram) to drive piles into the ground.

The impact force can be controlled more precisely than traditional diesel hammers or drop hammers, allowing it to be used in a variety of ground conditions.

Its low noise and vibration make it ideal for urban construction.

Its application in various construction sites, including buildings, bridges, offshore structures, ports, and oil fields, underscores its versatility.

Operating Mechanism

The hydraulic impact pile hammer functions by employing hydraulic pressure to raise and lower a hammer (ram), which in turn drives piles into the ground.

The hydraulic cylinder is responsible for raising the hammer, and the hammer, in turn, strikes the pile with great force, gradually inserting it into the ground.Impact strength is a adjustable feature, allowing for its use in a variety of ground conditions.This method ensures a constant supply of energy, and the adjustable impact force can maximize work efficiency.

Ram – the core component that delivers the blow

✅ Role:

– This is the most critical aspect, as it is responsible for imparting the impact force that is required to strike the pile

– It moves up and down via a hydraulic cylinder, generating impact energy to gradually insert the pile into the ground.

Features:

– The weight of the Ram and the impact velocity are critical factors that determine the power and striking force of the pile hammer.

– In general, heavier rams allow for deeper and stronger pile insertion.

– The adjustable impact force renders it suitable for utilization with various pile materials, including steel, concrete, and wood.

Drive Cap – a protective device that transmits impact force

✅ Role:

– The Ram does not directly strike the pile, but transmits the impact through the Drive Cap.

– It serves to protect the pile from damage by distributing the impact evenly.

✅ Features:

– Depending on the material of the pile (steel, concrete, wood), the Drive Cap is designed differently.

– These devices are designed to enhance the impact, thereby mitigating the risk of pile breakage and optimizing the transfer efficiency of impact forces.

– Customized Drive Caps are also available for specific projects.

Pile Cap – Pile protection and impact mitigation

✅ Role:

– Protects the top of the pile and acts as a shock mitigator when the impact is transmitted through the Drive Cap.

– It serves to distribute the blow so that the pile can be inserted into the ground evenly.

✅ Features:

– Different types of Pile Caps are used depending on the type of pile (steel, concrete, wood).

– If the Pile Cap is not properly fitted, the pile may lose its balance and become skewed.

– It is an important part that distributes the impact evenly, helping the pile to remain intact and have a long life.

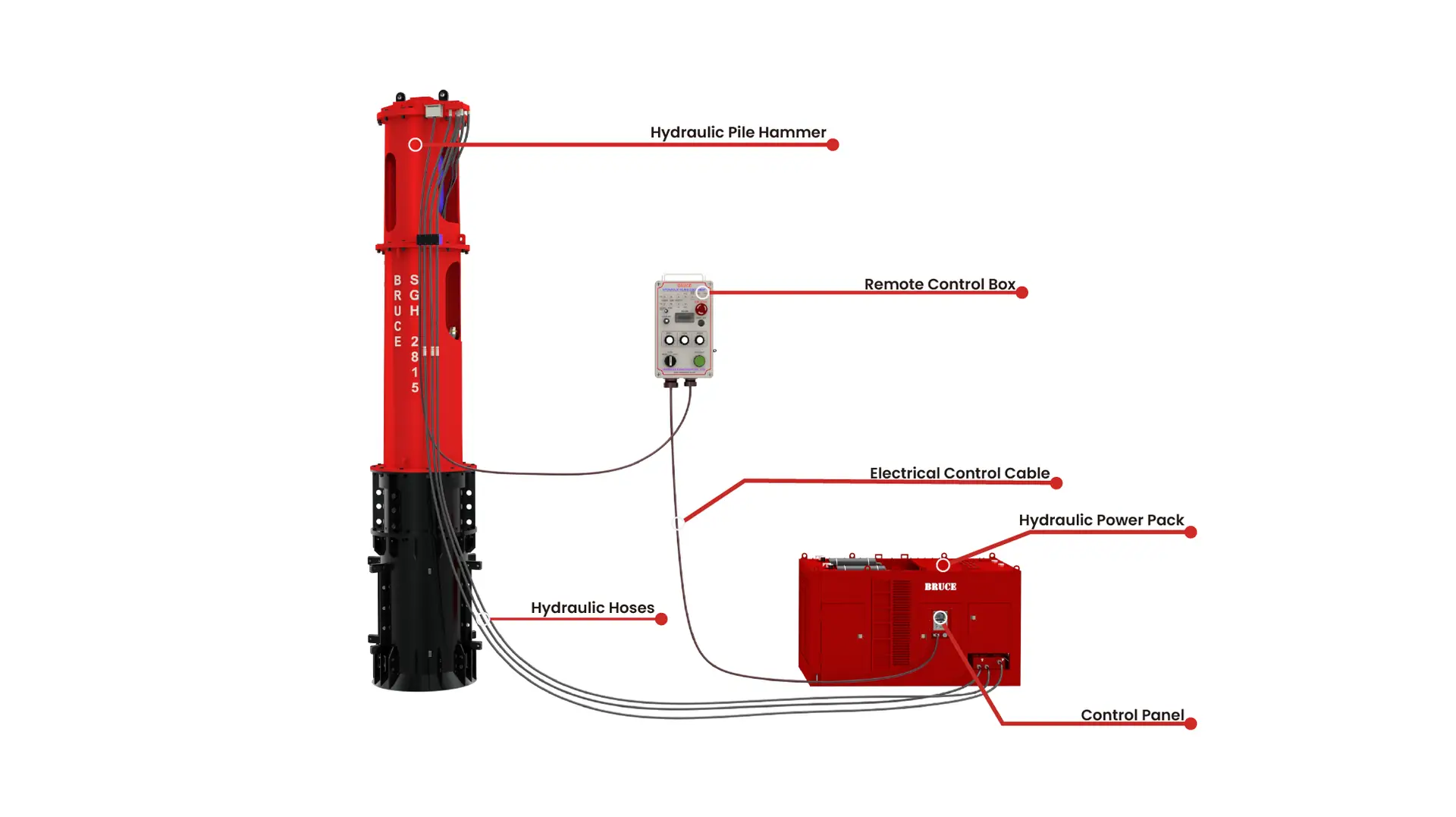

Power Pack – The energy source of the hydraulic system.

✅ Role:

– The key source of power to operate the hydraulic system.

– The primary function of the system is to facilitate the generation of high-pressure hydraulic oil by the hydraulic pump, thereby enabling the Ram to undergo vertical movement.

✅ Features:

– The apparatus’s output is adjustable, allowing it to adapt to different ground conditions and pile sizes.

– Provides a constant supply of high hydraulic pressure to maximize the speed and efficiency of piling operations.

Hydraulic Hose

✅ Role:

– It functions as a conduit through which the hydraulic pressure generated by the Power Pack is transmitted to the Ram and other hydraulic apparatus.

– The device’s primary function is to ensure a consistent supply of high-pressure hydraulic oil, thereby facilitating the uninterrupted operation of the hydraulic system.

✅ Features:

– Hydraulic hoses are engineered to be resilient and capable of withstanding elevated pressures.

– Different hose materials are used depending on the working environment (high temperature, low temperature, underwater work).

– Maintaining consistent hydraulic pressure is paramount to ensure the proper operation of the hammer and the consistency of the impact force.

– Regular maintenance is important to prevent leakage (hydraulic oil leakage) and breakage.

Remote Control Box

✅ Role:

– A control system that remotely controls the operation of the Hydraulic Impact Pile Hammer.

– It regulates the power output of the Power Pack, adjusts the impact strength of the Ram, controls the hydraulic oil flow, etc.

✅ Features:

– Designed for easy control of the hammer by the operator.

– Efficient work is possible by adjusting the impact force, speed, height, etc. of the hammer with just a button operation.

– Accurate impact force control allows for more precise pile insertion.

Benefits of the Hydraulic Impact Pile Hammer

Hydraulic Impact Pile Hammer offers many advantages over traditional impact hammers.

Low Noise & Vibration

– Low noise and vibration allows use in urban centers and environmental protection zones

– Minimizes impact on nearby structures and roads

Adjustable Impact Energy

– Impact force can be fine-tuned according to ground conditions

– Suitable for both hard rock layers and soft ground

High Energy Efficiency

– Reduces fuel consumption by using hydraulic system

– Continuous operation is possible, increasing working speed

Easy Maintenance

– Smooth operation reduces wear and tear on parts

– Lower maintenance costs than diesel hammers

Main Applications of Hydraulic Impact Pile Hammer

Hydraulic Impact Pile Hammer is utilized in various construction projects.

building foundation construction

– Construction of foundation piles for high-rise buildings and industrial facilities

– Providing a stable structure even in soft ground

Bridge and road construction

– Essential equipment for building road and railroad infrastructure

– Installation of piles for bridge foundations and substructures

Marine and harbor construction

– Foundation construction for docks, breakwaters, and offshore platforms

– Piles can be constructed underwater with strong impact force

Wind farms and infrastructure projects

– Used in offshore wind farms and large infrastructure works

– Widely utilized in green energy projects

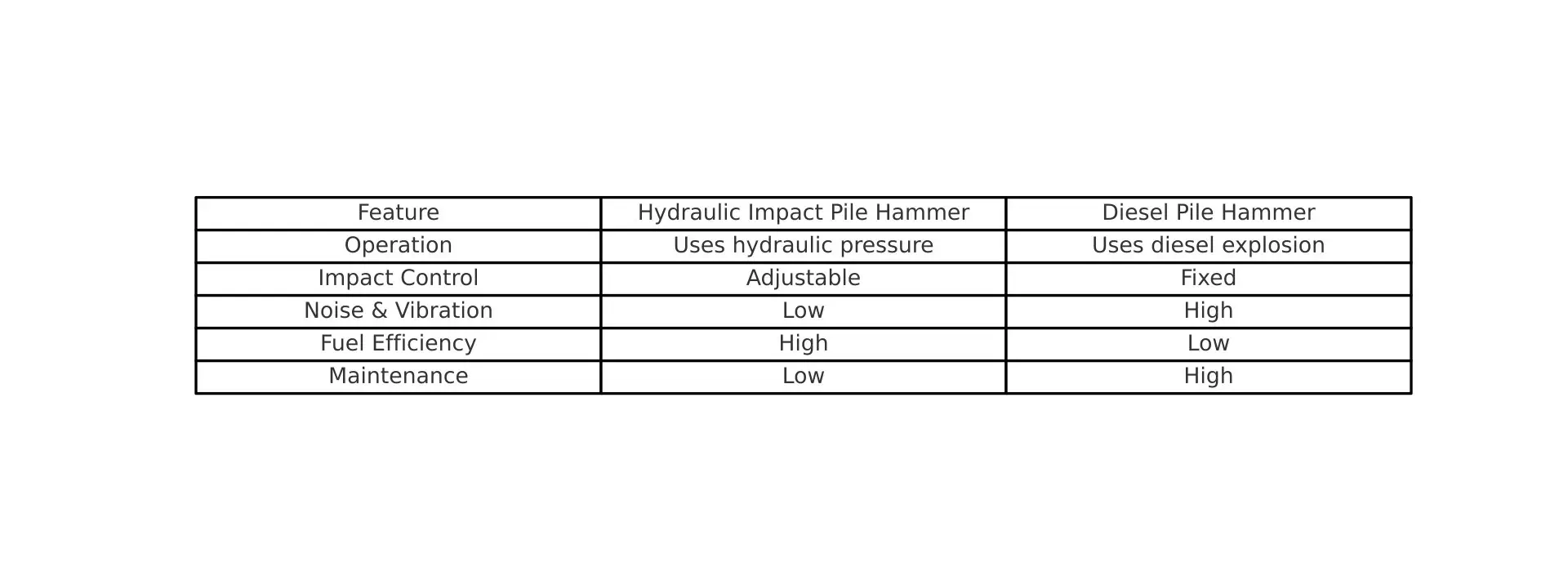

Hydraulic Impact Pile Hammer vs Diesel Pile Hammer Comparison