Vibratory Hammer is for driving and extracting piles

Bruce Hydraulic

Vibratory Hammer

Vibro Hammer & Vibratory Hammer

The BRUCE Hydraulic Vibratory Hammer is a hydraulic operated vibratory hammer used for driving sheet pile & H-Beam pile driving, casing pile as well as extracting the piles. It is simple and reliable, yet versatile, design allows for highly efficient, easy operation. Based on extensive studies, the BRUCE Hydraulic Vibratory Hammer uses sound waves – or vibrations – to greatly reduce or even eliminate ground resistance, making our pile drivers some of the best in the industry

Vibro Hammer

What is vibro hammer ?

A vibro hammer is a type of pile driving and pulling device that uses vibration to alter ground conditions, allowing it to drive piles into the ground and pull them out.

It is impressive how efficiently the vibro hammer can drive and extract different types of piles, such as sheet piles, formwork piles, and H-beams. The vibration dampers, which isolate vibrations, and the eccentric weights in the gearbox, which generate vertical vibrations, are crucial components that contribute to its effectiveness. Additionally, the synchronization of hydraulic motors and eccentric weights ensures precise and controlled pile driving. Overall, vibro hammers are indispensable tools for construction projects requiring pile installation and extraction.

A vibro hammer essentially consists of three main components: the damper, the gearbox, and the clamp. 1) The damper is mounted on top of the gearbox to isolate vibrations from the crane. 2) The gearbox contains eccentric weights that rotate in a vertical plane to generate vibrations. 3) The clamp is used to grip and hold the piles.

A vibro hammer is a type of pile driving and pulling device that uses vibration to alter ground conditions, allowing it to drive piles into the ground and pull them out.

It is impressive how efficiently the vibro hammer can drive and extract different types of piles, such as sheet piles, formwork piles, and H-beams. The vibration dampers, which isolate vibrations, and the eccentric weights in the gearbox, which generate vertical vibrations, are crucial components that contribute to its effectiveness. Additionally, the synchronization of hydraulic motors and eccentric weights ensures precise and controlled pile driving. Overall, vibro hammers are indispensable tools for construction projects requiring pile installation and extraction.

A vibro hammer essentially consists of three main components: the damper, the gearbox, and the clamp. 1) The damper is mounted on top of the gearbox to isolate vibrations from the crane. 2) The gearbox contains eccentric weights that rotate in a vertical plane to generate vibrations. 3) The clamp is used to grip and hold the piles.

What is vibratory hammer ?

A vibratory hammer or vibro hammer is a kind of pile driver and extractor that uses vibration to change the soil formations so that the vibro hammer can drive the piles into the ground and extract piles out of ground.

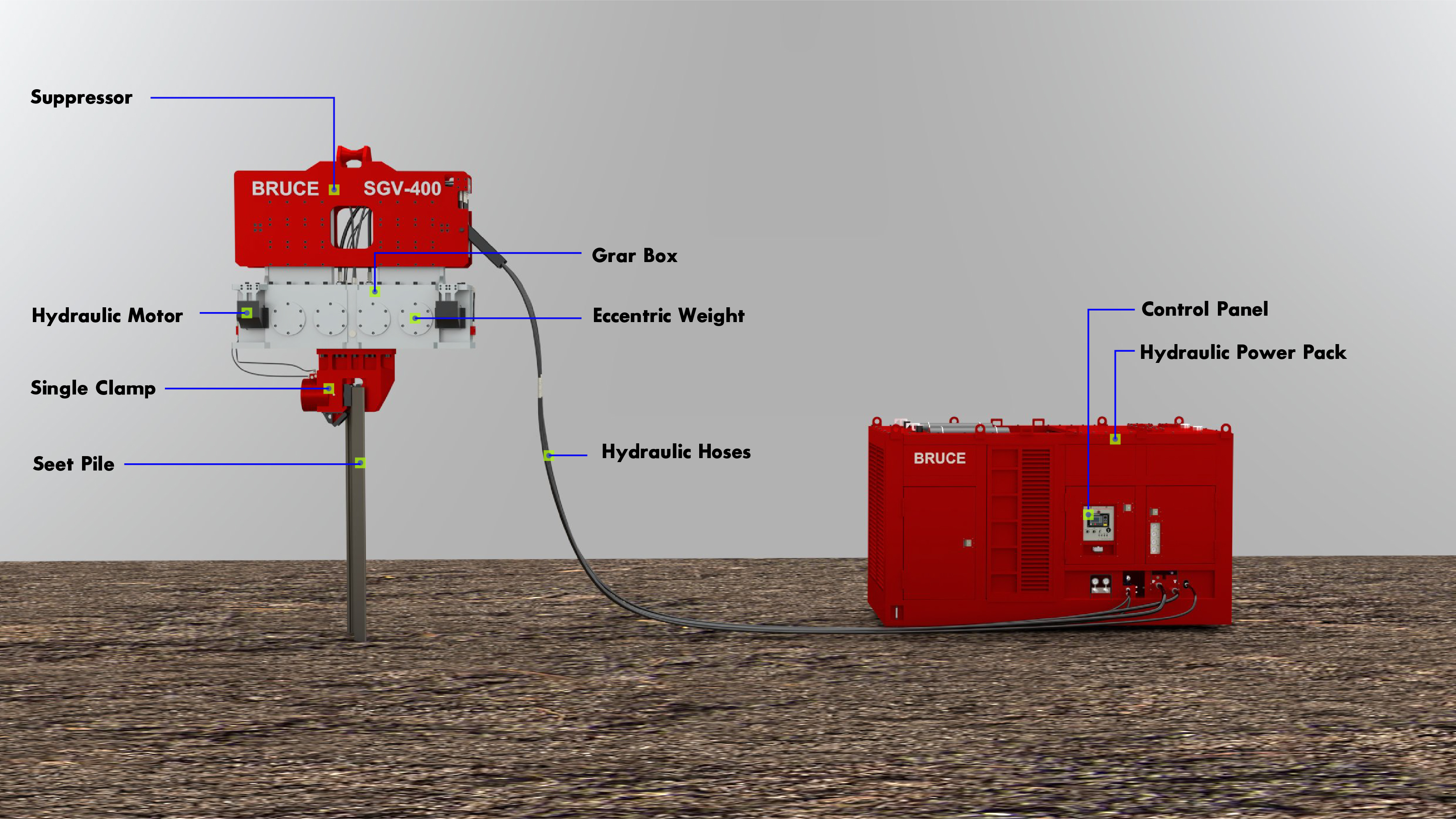

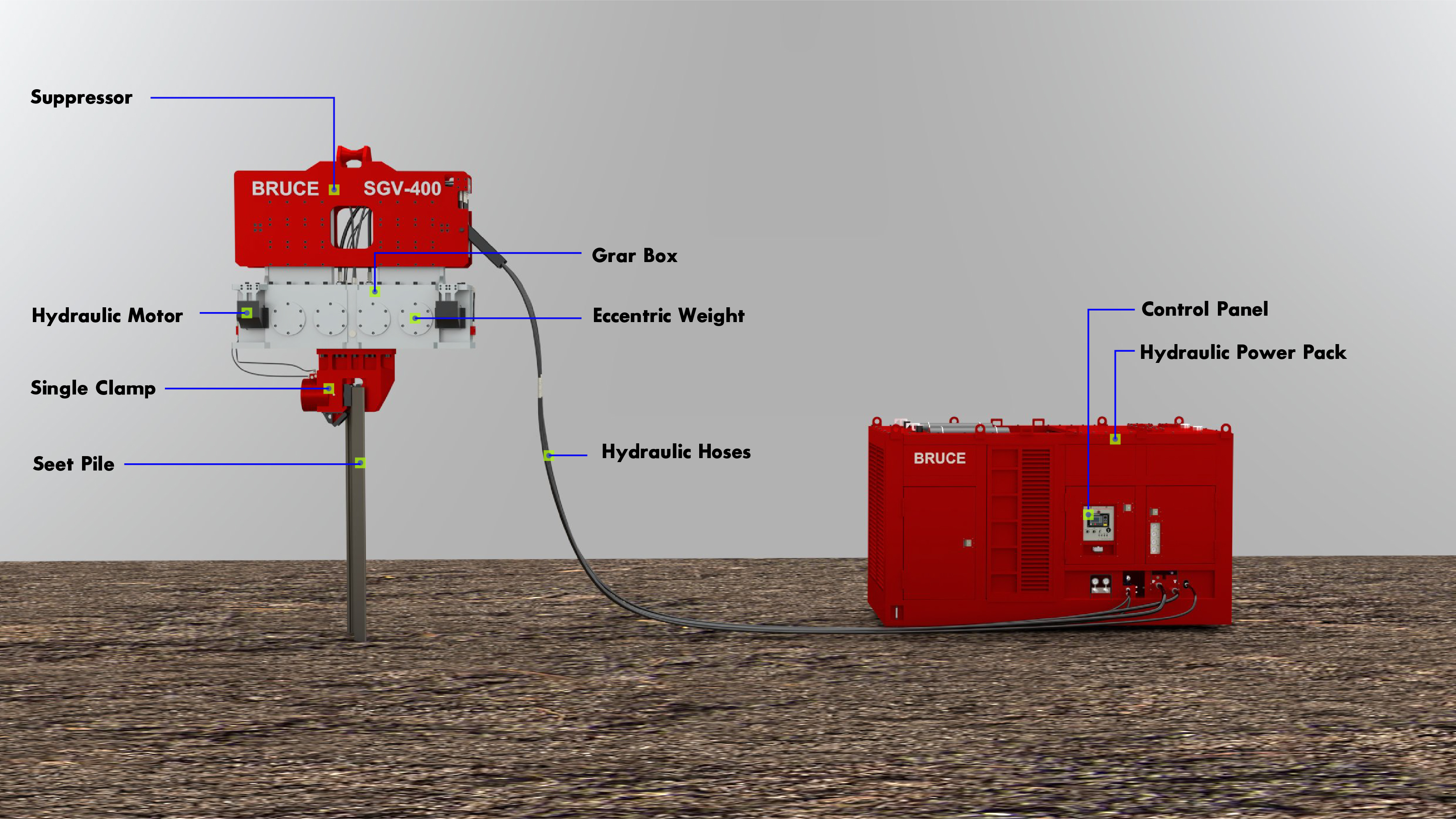

The functioning of vibro hammer to efficiently drive and extract various types of piles, such as sheet piles, casing piles, and H-Beams, is indeed impressive. The suppressor assembly's role in isolating vibration and the gear box's eccentric weights for generating vertical vibration are critical components that contribute to their effectiveness. Additionally, the synchronization of hydraulic motors and eccentric weights ensures precise and controlled pile driving. Overall, vibro hammers are essential tools for construction projects requiring pile installation and extraction.

There are major three components to a vibro hammer of the suppressor, gear box and the clamp that 1) the suppressor assembly is mounted on the top of the gear box to isolate vibration to the crane that vibro hammer contains elastomer rubbers that dampen the vibration reaching the crane boom,, 2) a gear box contains eccentric weights that rotate in a vertical plane to create vibration, 3) the clamp is for grab and hold piles.

The synchronized movement of the hydraulic motors and eccentric weights is key to generating the necessary vertical vibration while canceling out horizontal movement, allowing for precise and effective pile driving.

A vibratory hammer or vibro hammer is a kind of pile driver and extractor that uses vibration to change the soil formations so that the vibro hammer can drive the piles into the ground and extract piles out of ground.

The functioning of vibro hammer to efficiently drive and extract various types of piles, such as sheet piles, casing piles, and H-Beams, is indeed impressive. The suppressor assembly's role in isolating vibration and the gear box's eccentric weights for generating vertical vibration are critical components that contribute to their effectiveness. Additionally, the synchronization of hydraulic motors and eccentric weights ensures precise and controlled pile driving. Overall, vibro hammers are essential tools for construction projects requiring pile installation and extraction.

There are major three components to a vibro hammer of the suppressor, gear box and the clamp that 1) the suppressor assembly is mounted on the top of the gear box to isolate vibration to the crane that vibro hammer contains elastomer rubbers that dampen the vibration reaching the crane boom,, 2) a gear box contains eccentric weights that rotate in a vertical plane to create vibration, 3) the clamp is for grab and hold piles.

The synchronized movement of the hydraulic motors and eccentric weights is key to generating the necessary vertical vibration while canceling out horizontal movement, allowing for precise and effective pile driving.

The vibratory hammer is placed over the pile using large equipment such as cranes or excavators. The vibratory hammer is then attached to the pile with a series of clamps. A crane-mounted vibratory hammer is powered by a power unit with diesel engines and hydraulic pumps, which operate the hammer via hydraulic hoses. If the vibratory hammer is used with an excavator, it can be powered by the excavator’s engine.

Vibratory hammers are effective in various soil types, including clay, sand, and granular soils. They can also be modified for use underwater. Vibratory hammers are very large and commonly used in industrial settings. The use of vibratory hammers has many advantages. A vibratory hammer requires less force to drive a pile. Compared to other hammers used in similar situations, vibratory hammers are relatively quiet. They are often chosen for construction work in urban areas where the noise of a conventional pile hammer would be problematic. Vibratory hammers are also a good choice when the pile is located in an area with insufficient clearance for a conventional pile driver.

To choose the right vibratory hammer for a particular job, it is advisable to follow some general rules, such as considering soil conditions, the power of the vibratory hammer, the weight of the pile, the weight of the hammer, and the type of pile. Regarding soil conditions, it is definitely impossible to vibrate a pile in areas with larger stones or rocks.

On our website, http://www.powerquip.co.kr/products/hydraulic-vibratory-hammer_feature.html, you can get a brief overview of BRUCE vibratory hammers, including the types of carriers, main components, and comprehensive operating tables. We offer two different types of vibratory hammers, categorized by their carriers: the crane-suspended type and the excavator-mounted type, allowing customers to choose based on their work plan or current situation.

First of all, you must check whether your excavator has breaker lines, one being the pressure line and the other the return line. This is because the BRUCE excavator-mounted vibratory hammer is attached and activated via these lines. Next, you need to check whether your foot pedal is connected hydraulically or electrically. This is important because BRUCE's electrical connections differ slightly between hydraulic and electric foot pedals to ensure proper oil flow.

We are happy to recommend the BRUCE SGV-40 vibratory hammer for your excavator. The BRUCE excavator-mounted vibratory hammers are divided into three different models, depending on the capacity of the excavator. The SGV-40, for example, is designed and manufactured for attachment to excavators ranging from 20 to 30 tonnes. The SGV-60, on the other hand, can be adapted to excavators from 30 to 40 tonnes. The SGV-80E, the largest of the three, is recommended for excavators over 40 tonnes to ensure proper performance.

All new BRUCE power packs are supplied with Total Equivix ZS 46 (ISO, VG 46) hydraulic oil. Upon customer request, we can supply any type and brand of hydraulic oil. The fill level of the gearbox oil can be easily read from the level indicator on the center bottom of the gearbox. Under normal conditions and temperatures, the level should be in the center of the indicator. Due to the high operating temperatures, the preferred lubricating oil is a synthetic lubricant. They have good oxidation stability and also offer a much longer service life than natural lubricants. Mobile SHC 630 or 632 is used for splash lubrication of the gearbox. If the gearbox oil looks black or milky, drain the oil via the drain plug at the bottom of the gearbox and add new oil.

Yes, you are right! The elastomer rubbers play a very important role in absorbing the shocks delivered to the booms of the base machines during driving or extracting the hammer. We use two different types of elastomer rubbers, each with a maximum shear load of more than 2 tonnes. Additionally, a small safety bar inside the suppressor protects the elastomers from falling out during excessive crane pulling or extraction.